leeb hardness testing|units for rockwell hardness test : retailer Depending on the probe (“impact device”) and indenter (“impact body”) types that vary by geometry, size, weight, material and spring force, . See more

Medical autoclave sterilizers and low temp sterilizers manufactured by Tuttnauer for CSSD and operating room (OR) applications. Reliable and easy to operate with vacuum, liquid, gravity and flash cycles, we are very proud of the high quality of our healthcare autoclaves.

{plog:ftitle_list}

Discover how you can easily test your heating elements & learn how to replace them when you find out which one (s) are bad. Get Free Technical Support Here.

The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces (mainly above 1 kg). It measures the coefficient of restitution. It is a form of . See moreThe Equotip (later on also called simultaneously as Leeb method) rebound hardness test method was developed in the year 1975 by Leeb and Brandestini at Proceq SA to . See more

• German standards and specifications:• American standards:• Official international standards projects:• Official . See more

annular ligament tear test

• http://grhardnesstester.com/blog/methods-testing-hardness-steel/• https://www.baq.de/template.cgi?page=service_infos_ueber_messverfahren&rubrik=&id=&lang.The traditional methods are based on well-defined physical indentation hardness tests. Very hard indenters of defined geometries and sizes . See moreDepending on the probe (“impact device”) and indenter (“impact body”) types that vary by geometry, size, weight, material and spring force, . See more• Meyer hardness test See more

The Leeb hardness testing, otherwise called as Leeb Rebound Hardness Test (LRHT), is considered as one of the four commonly used methods to test the hardness of the .

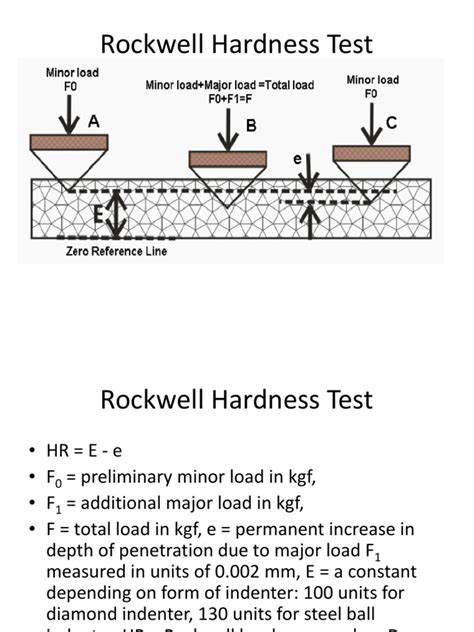

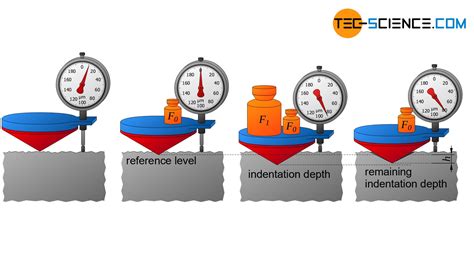

units for rockwell hardness test

The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces (mainly above 1 kg).The Leeb hardness testing, otherwise called as Leeb Rebound Hardness Test (LRHT), is considered as one of the four commonly used methods to test the hardness of the metal. It is a type of non-destructive testing used to inspect large sized workpieces weighing above 1 kg.

The Leeb hardness test is of the dynamic or rebound type, which primarily depends both on the plastic and on the elastic properties of the material being tested. The results obtained are indicative of the strength and dependent on the heat treatment of the material tested.Determination of the hardness of metallic materials according to Leeb is defined in the ISO 16859 and ASTM A956 standards. In this dynamic test method, the ratio of rebound velocity to impact velocity of a moving impactor is used to determine the hardness.

The Leeb hardness test is a non-destructive and portable method used primarily for metals. It involves a spring-loaded end with a spherical or conical indenter. The end that makes contact with the material is released, and the rebound velocity is measured after striking the material's surface.

Leeb hardness testing is a dynamic and robust method employed for determining the hardness of steel products, cast steel, and cast iron. Governed by the ASTM A956/A956M standard, this method utilizes the Leeb hardness principle to deliver fast and accurate measurements essential in various applications, from quality control to on-site metal . The Leeb hardness test (LHT with test value of L D), introduced in 1975 by Dietmar Leeb (Leeb 1979), is a portable hardness tester, developed originally for measuring the strength of metallic materials, that has been adapted for prediction of σ c of rock (Kompatscher 2004).

The Leeb rebound hardness test method was developed in year 1975 by Leeb and Brandestini at Proceq SA to provide a portable hardness test for metals. It was developed as an alternative to the unwieldy and sometimes intricate traditional hardness measuring equipment.

The Leeb hardness testing method uses a conical indenter and ball indenter to measure the hardness of a material. This article explains how this method works and its applications. The Leeb hardness test is a non-destructive testing method used to determine the hardness of a material. It is particularly useful for metals and alloys, providing a quick and accurate way to assess hardness without causing any damage to the sample.The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces (mainly above 1 kg).

The Leeb hardness testing, otherwise called as Leeb Rebound Hardness Test (LRHT), is considered as one of the four commonly used methods to test the hardness of the metal. It is a type of non-destructive testing used to inspect large sized workpieces weighing above 1 kg. The Leeb hardness test is of the dynamic or rebound type, which primarily depends both on the plastic and on the elastic properties of the material being tested. The results obtained are indicative of the strength and dependent on the heat treatment of the material tested.

answers to tests tears of a tiger

Determination of the hardness of metallic materials according to Leeb is defined in the ISO 16859 and ASTM A956 standards. In this dynamic test method, the ratio of rebound velocity to impact velocity of a moving impactor is used to determine the hardness.The Leeb hardness test is a non-destructive and portable method used primarily for metals. It involves a spring-loaded end with a spherical or conical indenter. The end that makes contact with the material is released, and the rebound velocity is measured after striking the material's surface. Leeb hardness testing is a dynamic and robust method employed for determining the hardness of steel products, cast steel, and cast iron. Governed by the ASTM A956/A956M standard, this method utilizes the Leeb hardness principle to deliver fast and accurate measurements essential in various applications, from quality control to on-site metal . The Leeb hardness test (LHT with test value of L D), introduced in 1975 by Dietmar Leeb (Leeb 1979), is a portable hardness tester, developed originally for measuring the strength of metallic materials, that has been adapted for prediction of σ c of rock (Kompatscher 2004).

The Leeb rebound hardness test method was developed in year 1975 by Leeb and Brandestini at Proceq SA to provide a portable hardness test for metals. It was developed as an alternative to the unwieldy and sometimes intricate traditional hardness measuring equipment.The Leeb hardness testing method uses a conical indenter and ball indenter to measure the hardness of a material. This article explains how this method works and its applications.

types of rockwell hardness test

portable leeb hardness tester

anterior acetabular labral tear test

leebs hardness chart

Understanding the design and operational specifications of your autoclave is key, as .The autoclave operates with saturated steam as the sterilizing agent with a temperature range from 105 °C (221°F) to 138 °C (280 °F) and a working pressure that meets ASME and PED

leeb hardness testing|units for rockwell hardness test